This week Flow Science released a new version of FLOW-3D Cast, its software specially-designed for metal casters. FLOW-3D Cast v4.1 offers powerful advances in modeling capabilities, accuracy and performance.

“One of the most exciting new features, Active Simulation Control, gives users the ability to control time-dependent events. For example, the transition to the fast shot stage during high pressure die casting filling can be synchronized with metal arriving at the in-gates. Die casting users will also benefit from the addition of a squeeze pin model, a faster and more accurate thermal die cycling model, and the ability to use a P-Q2 diagram to realistically control the motion of the shot sleeve plunger. Two other featured enhancements include the automation of post-processing and report generation. With batch post-processing, users can request their results ahead of time and then generate HTML-based reports that can be easily shared to communicate results and analyses.”

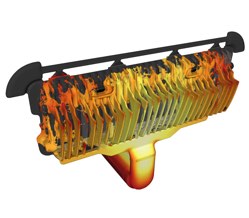

In this video, an HPDC simulation is shown where fast shot is automatically triggered when the fluid reaches the gates. The triggering process is automated through the new Active Simulation Control feature. The plunger motion during the slow shot has been calculated using the Barkhudarov method to minimize the amount of air entrained into the melt in the shot sleeve. This results in much higher quality castings and reduced scrap rates.