In this week’s Sponsored Post, Zack Fanning from Asetek explains how enhanced air cooling offers a lower cost alternative to liquid cooling.

Although liquid cooling is considered by many to be the future for data centers, the fact remains that there are some who do not yet need to make a full transformation to liquid cooling. Others are restricted until the next budget cycle. Whatever the reason, data centers may be unable near term to implement liquid cooling enhancements to their facilities.

Yet for many of these same data centers, they are facing issues that purely air cooled servers are unable to address. In some cases, the need for higher performance CPUs and GPUs in one or two U servers (packed into high density server racks) exceeds the ability of air flow to provide sufficient cooling. In other cases, such as high frequency trading, competitive imperatives demand that nodes be overclocked.

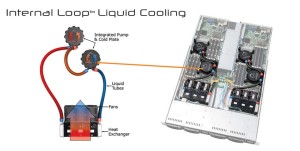

It is for these data centers that Asetek Internal Loop™ Liquid Cooling is ideal. Internal Loop replaces less efficient air coolers and enables data centers to utilize the highest performing CPUs and GPUs without change to data center infrastructure.

Interestingly, Asetek Internal Loop is actually “Liquid Enhanced Air” cooling the server nodes. Simply put, hot water is used to pull the heat from high heat flux components. The internal radiators inside the node then dump that heat into the air stream. This approach enables the heat that traditional air heat sinks cannot handle to be transferred into the data center without exceeding the thermal limits of the server’s components.

At the same time, Internal Loop can serve as a transitional technology from air cooling to Asetek’s “free cooling” solution RackCDU D2C. Unlike Asetek RackCDU D2C, Internal Loop still exhausts 100% of its hot air into the data center to be cooled using expensive chillers. Internal Loop can also serve as a proof point for IT and Facilities management who understand the benefits of liquid cooling but must deal with management fears of liquid cooling in the data center.

Internal Loop uses Asetek’s patented, high efficiency, sealed loop liquid cooling technology to cool the highest wattage, high heat flux CPUs and GPUs. With over 2 million units in the field, Asetek’s proven cold plate and pump design enables the superior cooling characteristics of liquid to capture more heat and transfer it into the air. Unlike competing liquid cooling designs, data center operators never need to touch the liquid or refill Asetek coolers. This same technology is already in service and cooling millions of CPUs and GPUs in PCs, workstations and servers.

Internal Loop is compatible with 1U and above form factor servers and blades. The low profile Asetek integrated pump / cold plate units have interchangeable mounting mechanisms compatible with Intel and AMD server sockets. Liquid-to-air heat exchangers are available in multiple form factors and are scalable to almost any performance or density requirement.

Internal Loop Liquid Cooling is currently available in CIARA’s ORION HF320D-G3, the first overclocked 2U 2-Node design ever to ship. CIARA is a leader in servers for high-frequency trading and uses liquid cooling to achieve the highest throughput for the demands of that market. Using Internal Loop has helped CIARA reach a new level of ultra high performance, speed and low latency while doubling the density of its previous ORION HF210 and 320 servers.

Zack Fanning is the Marketing Communications Manager at Asetek. To learn more about Asetek Internal Loop, visit Asetek.com.