In this video from ISC 2016, Olivier de Laet from Calyos describes the company’s innovative cooling technology for high performance computing.

In this video from ISC 2016, Olivier de Laet from Calyos describes the company’s innovative cooling technology for high performance computing.

“The HPC industry is ever facing is facing the challenge of ever-increasing cooling requirements. While liquid cooling cooling looks to be the best solution, what if you could achieve the same efficiencies without out using water and pumps? Enter Calytronics, cooling technology that is as simple as a heat pipe and as performant as liquid cooling.”

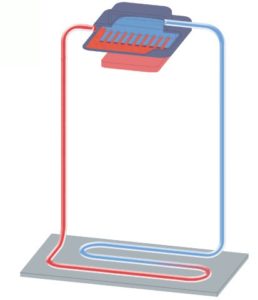

Calytronics cooling solutions are based upon Loop Heat Pipe (LHP) technologies. A Loop Heat Pipe is a sealed 2-phase cooling device composed of an evaporator (with integrated capillary pump), a tubed condenser and connecting lines. It contains an inner thermal working fluid thanks to which the heat transfer is done through continuing passive cycles of vaporization and condensation. It relies on 3 keys physical phenomena:

Calytronics cooling solutions are based upon Loop Heat Pipe (LHP) technologies. A Loop Heat Pipe is a sealed 2-phase cooling device composed of an evaporator (with integrated capillary pump), a tubed condenser and connecting lines. It contains an inner thermal working fluid thanks to which the heat transfer is done through continuing passive cycles of vaporization and condensation. It relies on 3 keys physical phenomena:

- Capillary Pumping. Calyos evaporators contain an inner capillary pump made of a metallic foam with micron level pores. While absorbing the fluid, the foam creates a natural pressure head that makes the fluid circulates inside the loop. It allows pumping without any mechanical pump nor external energy. Calyos breakthrough manufacturing processes make pumping against gravity possible up to 3 meters.

- Vaporization. After being pumped, the fluid fully vaporizes by absorbing the heat dissipated by the component to be cooled (the “hotsource”). Thanks to the latent heat of vaporization, high heat loads (with heat fluxes up to 100W/cm²) can be easily transferred whilst the thermal resistance is significantly reduced compared to other cooling technologies.

- Condensation. Thanks to the pressure head, the vapor (100% vapor quality) passively flows to the condenser where it turns back into liquid (0% vapor quality) whilst the heat is released outside the Loop Heat Pipe with an external Heat Exchanger (the “cold-source”). Once fully condensed, the liquid flows back to the evaporator to start a new cycle.

In recent news, Calyos announced that the company is expanding production with a move to a larger plant at the end of June. The 3600 M2 factory will have manufacturing capacity of up to 70,000 units per month.