The US National Institute of Standards and Technology (NIST) is leading a collaborative project with industrial partners to standardize 3-D models to exchange information across design and manufacturing in one seamless “digital thread.”

The US National Institute of Standards and Technology (NIST) is leading a collaborative project with industrial partners to standardize 3-D models to exchange information across design and manufacturing in one seamless “digital thread.”

The Design to Manufacturing and Inspection Project will make use of a new international standard for incorporating computer-readable product and manufacturing information (PMI) into 3D models that do not require human interpretation of graphical depictions and data re-entry.

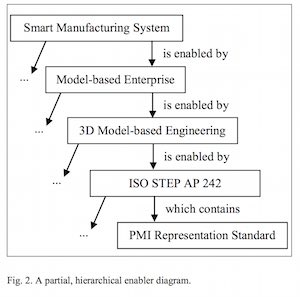

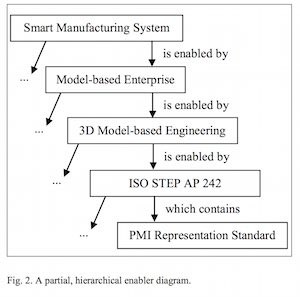

The standard, recently published by the International Organization for Standardization, ISO 10303-242 (also known as STEP AP 242) enables designers, process and systems engineers to embed 3D representations of parts with actionable specifications for materials, geometrical and dimensional tolerances, surface texture, as well as process notes, finish requirements and other information. A report on this work was recently published on the NIST website.

The standard, recently published by the International Organization for Standardization, ISO 10303-242 (also known as STEP AP 242) enables designers, process and systems engineers to embed 3D representations of parts with actionable specifications for materials, geometrical and dimensional tolerances, surface texture, as well as process notes, finish requirements and other information. A report on this work was recently published on the NIST website.

STEP AP 242 serves as a mediator between programs from different vendors. A part design prepared with proprietary software is converted into the common language, format and protocols of STEP AP 242 so it can be read by another vendor’s software, which typically re-translates the design instructions into its native language.

In the new NIST project, Rockwell Collins, an Iowa-based manufacturer of avionics and communication equipment for defense and commercial applications, will use its CAD system to generate a 3D design of a part, complete with all feature tolerances and other specifications. The design will be translated into STEP AP 242 so that Geater, an aerospace supplier located in Independence, Iowa, can re-purpose the model to generate machining instructions. Separately, Geater will reuse the STEPAP 242 model, with no manual data entry, to generate code that will direct a coordinate measuring machine to perform the inspection measurements necessary to determine whether the part is manufactured as designed.

The NIST researchers and their industrial partners hope to demonstrate the feasibility—and benchmark the advantages—of using the standardized, three-dimensional. These 3D models embedded with data and instructions that computers can parse and process are expected to open up significant opportunities including reduced cycle time and cost, less duplication of effort, lower risk of errors, increased part yields and higher-quality products.

An alternative approach to achieving smooth exchanges of information across the full range of manufacturing-related operations is to use software from one vendor. However, this approach locks a company into a single proprietary solution, and it is not practical for companies to exchange product and manufacturing information with many suppliers and customers.

A full-scale demonstration of end-to-end interoperability is expected by summer 2015. In follow-on work, NIST researchers will focus on strengthening and extending the digital thread to link a broader range of manufacturing-related activities such as assembly, bidding, engineering changes, in-process inspection, and visualization and collaboration.

NIST systems analyst Allison Barnard Feeney, leader of the project stated: “Three dimensional model-based engineering is an important step toward ‘smart’ manufacturing systems. These systems will need to be autonomous, self-aware and self-correcting. At the same time, they must be able to work harmoniously with human supervision and collaboration.”

Collaborators in the NIST led project include interoperability-focused manufacturing-services providers International TechneGroup Incorporated (ITI), Milford, Ohio, and Advanced Collaboration Consulting Resources, Summerville, SC; Rockwell Collins; and Geater Machining and Manufacturing, Iowa. Other participants are CNC Software, Tolland, Conneticut, maker of computer-aided manufacturing (CAM) software; Mitutoyo America, a maker of measurement equipment and software; and software vendor CoreTechnologie, Rossford, Ohio.

This story appears here as part of a cross-publishing agreement with Scientific Computing World.

Learn how HPC is advancing the growth of manufacturing with this latest white paper from SGI / Intel.