Today GE announced a multi-year joint development agreement with Cascade Technologies to improve combustion simulation software. With new visualaztion capabilities, engineers can virtually look inside a gas turbine as it operates and gain a better understanding of the turbulent fluid, chemical and acoustic processes occurring within advanced, low-emissions gas-turbine combustion systems.

The global energy industry looks to GE as a leader in high efficiency, with current HA gas turbines designed to deliver more than 61 percent combined cycle efficiency. The enhanced simulation and visualization capabilities enabled by our collaboration with Cascade can help us deliver even higher efficiency and lower emissions in the next generation of gas turbines,” said John Lammas, vice president, power generation engineering at GE Power and Water. “Together, we’re working to deliver better products, faster.”

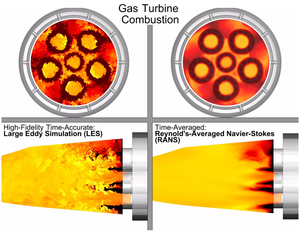

The gas turbine combustion process involves multiple steps at high speed. Compared to other digital modeling techniques, Cascade simulation software enables better visualization of the combustion process so engineers can understand more about the subtle changes that occur. It’s like looking at the world through a slow-motion video versus a time-lapse snapshot.

GE is leading the industry by deploying this technology in their engineering,” said Frank Ham, president and CEO, Cascade. “The simulation is like a modern-day digital microscope that allows GE engineers to interrogate the combustion process in ways that were not previously possible. Seeing these details is helping GE gain critical knowledge in how they can continue to improve their gas turbines.”

This visualization is made possible by unique code software that can be scaled to run on national laboratory super-computers and at other high-performance computing facilities. The code allows GE and Cascade teams to simulate the combustion process with microsecond time fidelity and sub-millimeter resolution, while generating petabytes of data.

Such an unprecedented amount of information combined with proprietary web-based analysis tools can help shorten the path between simulations and engineering insight. During a typical two-year development cycle, engineers utilizing the full potential of the software can iterate on a design up to ten times faster to accelerate learning and improve the design.

Working with GE’s advanced engineering design, Cascade can have the most impact by both improving the software and helping GE improve the gas turbine technology iteratively,” said Ham. “By providing information that goes into design decisions, we can help improve efficiency, lower emissions and increase durability in future products.”

The link to Cascade Technologies has been corrected.