Researchers are using Argonne supercomputers to jump-start internal-combustion engine designs in the name of conservation.

Even with the push toward electrification in the automotive sector, it’s estimated that there are over 200 million internal combustion engines sold a year,” says Sibendu Som, an Argonne Energy Systems Division mechanical engineer who is technical lead investigator for the lab’s Virtual Engine Research Institute and Fuels Initiative (VERIFI). “Improving engine efficiencies by even a few percentage points can take a big chunk out of our carbon footprint. We are working on a proof-of-concept to demonstrate how simulating several thousand engine configurations simultaneously can really help engineers zero in on the optimum engine designs and operating strategies to maximize efficiency while minimizing harmful emissions.”

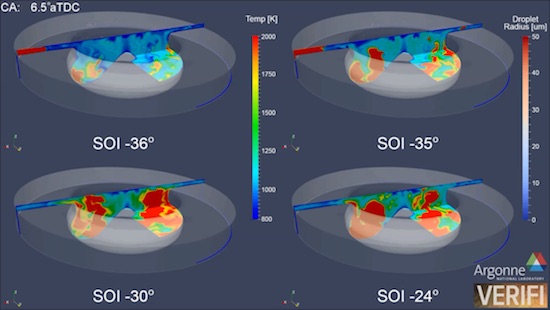

Images from fluid dynamics simulations of a gasoline compression engine – in which gasoline burns in a diesel engine purely through compression, a method that produces less soot and oxides of nitrogen than diesel combustion – compare an earlier start (top) of injection timing (or SOI, as stated in degrees: higher = earlier) to a later SOI timing (bottom).

To do this, Som and colleagues are using 60 million processor hours on Mira, an IBM Blue Gene/Q at the Argonne Leadership Computing Facility (ALCF). The computing time is through the Department of Energy’s Advanced Scientific Computing Research Leadership Computing Challenge program. Som’s co-investigators include fellow mechanical engineer Janardhan Kodavasal, ALCF principal project specialist Marta García and ALCF senior software developer Kevin Harms.

Industry researchers may run perhaps tens of simulations at a time to reduce the costly need to build physical prototypes when evaluating new engine designs, Som says. But “we are talking about running on the order of 10,000 engine simulations concurrently (because) piston shape, injector design, valve and fuel injection strategies, and fuel composition need to be evaluated simultaneously.” Until recently, running thousands of simultaneous simulations “was not possible because computing resources were not there, nor the technology. In this project we have access to both.”

By “technology,” Som means special coding. The VERIFI team’s main engine simulation code is CONVERGE, fluid dynamics software made by Convergent Science. The program constantly updates conditions in the engine model to track changeable elements like moving parts. The group also uses a high-level and resilient parallel programming language called Swift, developed by Argonne’s Mathematics and Computer Science Division, to orchestrate the multitude of independent simulations running concurrently on Mira. Swift, Som adds, can execute thousands of simulations at once without overburdening Mira’s infrastructure.

A paper Kodavasal, Harms, García, Som and others published this year in the Journal of Energy Resources Technology describes the development of another VERIFI adaptation: a so-called stiffness-based algorithm that spreads out the parallel-processing loads on high-performance computers.

We’re trying to make sure that every processor is solving the same amount of computational work,” Kodavasal explains. With their innovations, the authors say, a simulation of multiple versions of an advanced combustion chamber at one stage of an engine cycle ran more than three times faster while using 4,096 Mira cores.

With all those tools, the Argonne group can load up crucial details as it models, among other things, turbulence, combustion chemistry and how much heat is lost as waste energy within the engine head, cylinder walls and pistons. All those calculations – done at every simulation time step – can translate into a single color-coded image of fuel spraying in as a piston nears its top-center position, at the end of its compression stroke with ignition about to occur. Som says all of a four-stroke engine’s cycles can be similarly detailed. A single engine cycle happens in a blink, but “the computer can take several hours to simulate this.”

Source: Department of Energy

Sign up for our insideHPC Newsletter