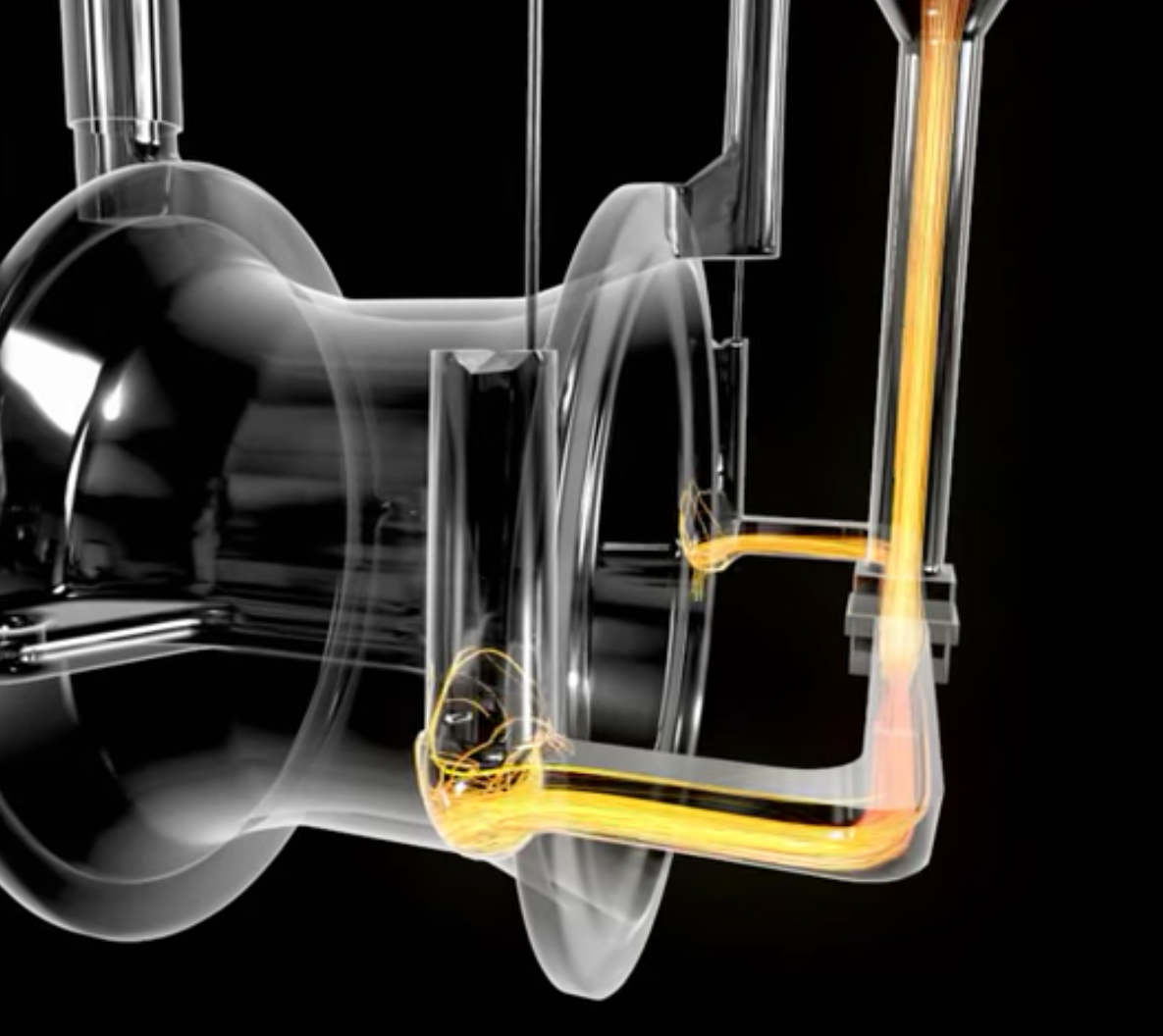

In this video courtesy of DENIZCILLER, the sand casting process is simulated with ESI ProCAST and QuikCAST.

In this video courtesy of DENIZCILLER, the sand casting process is simulated with ESI ProCAST and QuikCAST.

“Cast iron has an ability to expand during the liquid to solid phase change,” explains Badarinath Kalkunte, casting product marketing and business development manager at ESI Group. “Expansion is due to the fact that graphite present in cast iron can form nodular structures that occupy more volume. Interrupting the possible volume change due to this expansion could help in reducing pores. This is the reason why feeder necks are designed to arrest the expansion of cast parts and thereby compensate for shrinkage porosity.”

Simulations like this help foundry engineers understand how metal expands and contracts during the casting process, thereby predicting the final locations of shrinkage porosity. Several other possible defects can occur during a casting process causing imperfection to the final product. To reduce or eliminate these defects, a well-designed gating and feeding system needs to be developed.

Read the Full Story