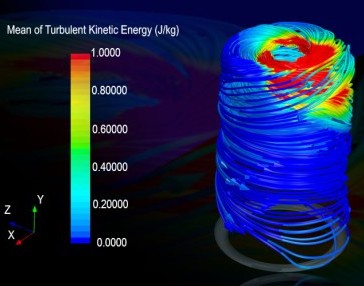

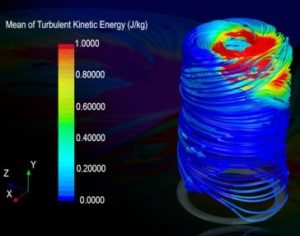

An HPC4Manufacturing collaboration between Lawrence Livermore National Laboratory and powder flavor company ZoomEssence seeks to employ HPC modeling and simulation to improve the flow of air in industrial scale driers and optimize the drying process. In the image, the flow stream lines are colored by the turbulent kinetic energy in the flow.

The Department of Energy is seeking industry proposals for public/private projects aimed at applying high performance computing to industry challenges for the advancement of energy innovation.

Since the inception of the program we have worked with both large and small companies in a variety of industrial sectors to advance the use of high performance computing in US manufacturing,” said HPC4Mfg’s Director Lori Diachin of LLNL. “We are seeing some significant successes with orders of magnitude reduction in simulation times and higher fidelity simulations that more closely match the reality of the manufacturing process. With this solicitation we plan to continue to expand the reach of our program to new companies to help solve new and different problems.”

The funding represents the latest round of solicitations for the High Performance Computing for Manufacturing (HPC4Mfg) program, led by Lawrence Livermore National Laboratory (LLNL), in partnership with the Oak Ridge and Lawrence Berkeley national laboratories. The program provides manufacturers access to the DOE national laboratories’ supercomputing systems as well as the expertise of lab computing experts. This solicitation marks the fifth round of funding since the program began in 2015.

The HPC4Mfg program, funded out of the Advanced Manufacturing Office (AMO) within DOE’s Office of Energy Efficiency and Renewable Energy (EERE), is seeking proposals requiring intensive modeling and simulation to overcome manufacturing process challenges that could result in reduced energy consumption, increased productivity, improved clean energy technology design and clean energy manufacturing, with a potential for broad national impact.

DOE will award selected projects up to $300,000 to support compute cycles and work performed by the national lab partners. Selected industry partners will provide at least 20 percent of in-kind funding for the projects. Follow-on funding for previously-awarded projects that have already been successfully demonstrated also will be considered. Selected follow-on projects will be awarded up to $300,000 with industry providing a 50 percent cost share, at least half of which must be cash.

To date, through the HPC4Manufacturing program, DOE has awarded approximately $15 million for 47 projects, ranging from improving energy efficiency in paper making and automobile engines to improving the reliability of wind turbines and reducing defects in 3D-printed parts. The program recently expanded to include projects to develop new or modified materials for extreme conditions under the High Performance Computing for Materials (HPC4Mtls) program, which is beginning its first round of solicitations.

HPC4Mfg’s computing resources are provided through a variety of mechanisms, including the Advanced Scientific Computing Research Program within DOE’s Office of Science Leadership Computing Challenge allocation program, as well as allocations at the National Renewable Energy Laboratory, the National Energy Technology Laboratory, Los Alamos National Laboratory and Sandia National Laboratory.

Concept Papers are due March 15, 2018. Final selections will be announced in July 2018.