The Department of Energy today announced the first round of awardees for the new HPC4Materials (HPC4Mtls) Program, a public-private effort aimed at using high-performance computing to advance U.S. industry’s discovery, design and development of materials for severe environments.

The Department of Energy today announced the first round of awardees for the new HPC4Materials (HPC4Mtls) Program, a public-private effort aimed at using high-performance computing to advance U.S. industry’s discovery, design and development of materials for severe environments.

The nine projects, totaling $2.7 million in DOE funding, involve five national laboratories and eight private companies, including Ford Motor Company, Siemens Energy, Shell International Exploration and Pratt & Whitney. Lawrence Livermore National Laboratory leads the HPC4Mtls Program, partnering with Los Alamos, Pacific Northwest, and Oak Ridge national laboratories and the National Energy Technologies Laboratory (NETL).

We are excited about adding a materials portfolio to the HPC4EnergyInnovation umbrella program,” said acting HPC4Materials Director Robin Miles. “Understanding material properties at the macro level based on atomic scale effects is a sweet spot for HPC capabilities. New materials are essential for improved energy efficiency in electrical power plants and advanced vehicles.”

LLNL will work with the United Technologies Research Center to use large-scale quantum chemical simulations to understand the complex mechanisms behind hot corrosion degradation. Another project, with the Carpenter Technology Corporation, will seek to develop a predictive model of novel materials with properties including strength.

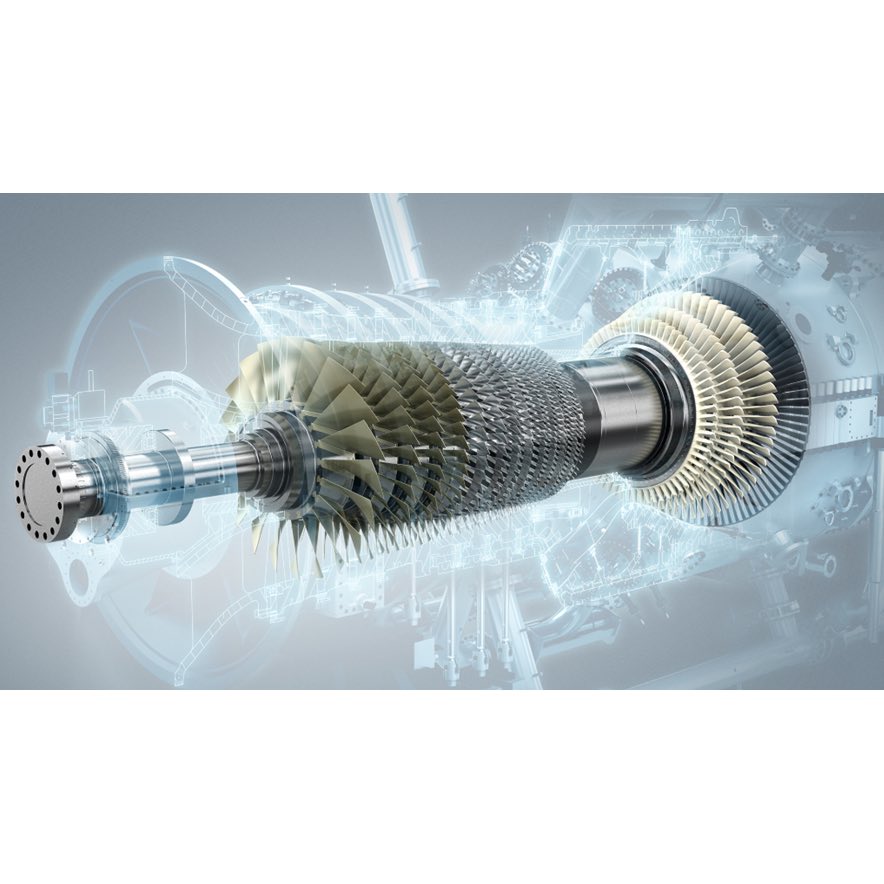

Other projects include ORNL and Strategic Power Systems, Inc. working to use HPC analysis of materials to optimize power plant performance and availability; LANL collaborating with Siemens Energy, Inc. on HPC modeling and simulations to understand material imperfections of critical fossil power generation components; SNL combining with Skyhaven Systems, LLC on safe and efficient hydrogen refueling of fuel-cell vehicles; ORNL and Ford Motor Company collaborating on a project to improve predictions of crash responses of carbon composites in auto parts; NETL working with Strategic Power Systems, Inc. to predict failure in heat recovery steam generators to mitigate damage and for predictive maintenance; ORNL joining forces with Pratt & Whitney to predict material responses in advanced turbine gas engines; and ORNL and Shell International Exploration and Production working to simulate heat and mass transport phenomena in molten metal reactors.

Through the HPC4Mtls Program, industry partners will have access to the DOE national laboratories’ HPC systems, and access to the labs’ expertise in computational fluid dynamics, materials modeling, additive manufacture and other material-focused problems.

The HPC4Mtls Program is part of the HPC4EnergyInnovation Initiative, comprised of the DOE Office of Fossil Energy, the Office of Energy Efficiency and Renewable Energy and the Office of Science. Of the funding from DOE, $1.5 million will come from the Office of Fossil Energy. DOE’s Vehicle Technologies Office and Fuel Cell Technologies Office will contribute $600,000 to two projects apiece. The industry partners were all required to put forth at least 20 percent of project costs, a minimum of $60,000.

Sign up for our insideHPC Newsletter