[SPONSORED GUEST ARTICLE] Geopolitical change is having tectonic impact on the global manufacturing industry. In the U.S., western Europe and other industrialized countries, there is growing emphasis on “manufacturing repatriation,” or reshoring. With this comes the need for new strategies leveraging data analytics, machine learning, robotics and advanced design simulation enabled by HPC-class compute power to help contain costs, improve quality and accelerate time-to-market.

[SPONSORED GUEST ARTICLE] Geopolitical change is having tectonic impact on the global manufacturing industry. In the U.S., western Europe and other industrialized countries, there is growing emphasis on “manufacturing repatriation,” or reshoring. With this comes the need for new strategies leveraging data analytics, machine learning, robotics and advanced design simulation enabled by HPC-class compute power to help contain costs, improve quality and accelerate time-to-market.

At the heart of these strategies for many companies: a cloud computing platform that offers – and continually refreshes – its technology and support service ecosystem for manufacturers.

source: National Institute of Standards and Technology

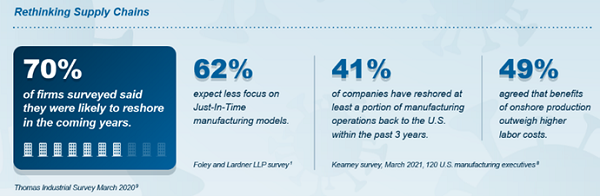

The reasons for reshoring are many. A recent article in Design News cited a report by the National Institute of Standards and Technology stating that “the reshoring of manufacturing back to the US has been top of mind for many manufacturers, especially in light of the supply chain issues brought on by the pandemic. Proximity to customers and markets, eco-system synergies, and the impact on the domestic economy are all reasons why manufacturers want to move production back to the U.S.”

Growing geopolitical tensions and trade restrictions are another risk factor pushing manufacturers to develop domestic manufacturing capacity. It’s the reverse of the decades-long off-shoring trend that began in the 1960s, spurred by cheaper labor and more lenient regulatory regimes in Asian and other countries. But with the pendulum swinging back toward repatriation, manufacturers are looking to world-class technology strategies and practices enabling them to remain competitive.

Azure’s Manufacturing Ecosystem

Microsoft Azure, one of the world’s leading high-performance cloud platforms, offers extensive experience in the manufacturing sector. Critical to that support is Azure’s rapid adoption and integration of the newest, most high performant technologies. For example, Azure has developed a track record of being the first public cloud provider to adopt newly released AMD microprocessors, including the latest AMD EPYC CPUs and AMD Radeon Instinct GPUs, two of the hottest chips in the HPC industry.

“More powerful compute has two major implications for manufacturers,” said Cédric Husianycia, EMEA HPC Solutions Specialist at Microsoft. “It means engineers can generate more design simulations in less time – and more simulations means a greater likelihood of developing an optimized product that meets the manufacturer’s goals.

source: Shutterstock

“It also means they can run multi-physics based simulations of greater scope, scale and complexity,” Husianycia said. “Using the latest-and-greatest microprocessors enables shorter product design and production life cycles, and it enables the design of more sophisticated, more advanced products. It’s a win-win for manufacturers. Our close relationship with AMD, getting their chips into usage among our manufacturing customers, is a core part of the Azure offering.”

Another critical benefit of the Azure cloud: elastic expansion or contraction of the compute resources required at a given time by manufacturers. And because compute resources are expensive and workloads are increasingly compute-intensive, expansion of resources is usually the case.

This contrasts with on-premises IT infrastructures that often cannot meet compute demand, forcing engineers and other end-users to wait in a queue – what’s referred to in the industry as an “environment of constraint.” On-prem infrastructures manufacturers typically have a three-to-five-year life cycle, which means that by the end of the cycle the technology available to the engineering has become increasingly obsolete. By contrast, Azure continually installs newly available HPC-class technology.

That said, Azure cloud provides more than just HPC-class compute, it delivers an extensive array of hardware, software and networking capabilities required to deliver comprehensive solutions that manufacturers need.

Let’s look at examples of Azure customers who leverage the platform’s combination of advanced technology and support services.

Hexagon’s Design Simulation Software

Hexagon’s Manufacturing Intelligence division, which develops simulation software (its CAE simulation business was formerly known as MSC Software) for engineers to validate their designs using virtual prototypes. Customers use Hexagon solutions to complement or replace the physical build-and-test process. The software is used for linear and nonlinear finite element analysis (FEA), acoustics, fluid-structure interaction (FSI), multi-physics, optimization, fatigue and durability, multi-body dynamics, and control systems simulation.

Hexagon’s Manufacturing Intelligence division, which develops simulation software (its CAE simulation business was formerly known as MSC Software) for engineers to validate their designs using virtual prototypes. Customers use Hexagon solutions to complement or replace the physical build-and-test process. The software is used for linear and nonlinear finite element analysis (FEA), acoustics, fluid-structure interaction (FSI), multi-physics, optimization, fatigue and durability, multi-body dynamics, and control systems simulation.

Typical of its partnerships with manufacturing software vendors, Microsoft and Hexagon last March released the Hexagon CAE software deployment guide of Hexagon’s design and engineering software solutions on Azure, solutions such as MSC Nastran. The jointly developed guide includes the deployment steps needed to run Hexagon simulation solutions on the Azure HPC infrastructure as well as benchmark results.

According to Microsoft’s Lukasz Miroslaw, senior EMEA HPC & AI specialist, Azure Cyclecloud was used to orchestrate the definition, deployment and control of the HPC clusters used for testing. “Each cluster was equipped with the scheduler for job orchestration and leveraged the autoscaling feature,” Miroslaw said. “For example, the clusters were scaled out when jobs were submitted and scaled down when all the jobs were finished. For testing we used Slurm scheduler.”

He said the entire infrastructure was deployed in an Azure Virtual Network, which can be isolated from the internet and integrated with on-prem networking infrastructures to allow access from on-premises clients with protocols of choice, such as SSH to access the master node with a Slurm scheduler and HTTPS to access the Azure Cyclecloud User Interface.

To reduce installation complexity, Microsoft provides ready-to-use HPC images for configuration of Infiniband drivers, connectivity between the nodes as well as the MPI libraries. These images can then be automatically attached to the VMs in the clusters to automate deployment and provisioning.

Ansys Cloud Direct Configuration Guidance

Similarly, Ansys Cloud Direct offers configuration and optimization guidance for VDI & HPC with Microsoft Azure, providing access to Ansys simulation applications running on desktops and in browser. Developed in partnership with Azure and optimized for Ansys solvers, Ansys Cloud Direct is an avenue to nearly limitless computing resources.

Similarly, Ansys Cloud Direct offers configuration and optimization guidance for VDI & HPC with Microsoft Azure, providing access to Ansys simulation applications running on desktops and in browser. Developed in partnership with Azure and optimized for Ansys solvers, Ansys Cloud Direct is an avenue to nearly limitless computing resources.

“Seventy-five percent of Ansys customers say they face hardware barriers that prevent them from fully using the power of the software,” wrote Ansys Cloud Product Marketing Manager Thomas Lejeune in a blog. “Most of them work on computers with a low number of cores, and this problem has been exacerbated by the work-from-home situation during the COVID pandemic. With Ansys Cloud Direct, we partnered with Microsoft to deliver a unique HPC solution that features an optimized workflow, unprecedented performance and holistic support.”

Altair-Azure Partnership

![]() Altair makes a wide array of cloud software solutions for simulation, IoT, HPC, data analytics and AI that run on Azure.

Altair makes a wide array of cloud software solutions for simulation, IoT, HPC, data analytics and AI that run on Azure.

Cloud is an attractive option for customers with limited in-house resources. Altair notes that “with cloud computing resources like Azure, there’s theoretically no limit in terms of application scalability and potential job size. Users with time constraints can access more nodes in the cloud to get faster results, and organizations with on-premises data centers can burst to the cloud to run more models and get work done more quickly.”

Altair also offers the Altair Unlimited virtual appliance on the Azure marketplace, which offers turnkey, unlimited access to Altair solvers and HPC resource management.

Bridgestone’s Data Platform on Azure

Azure also digs into the details of data management. For example, with tire and mobility solutions stalwart Bridgestone, Azure is partnering on a large-scale digital transformation program aimed at improving operations, modernizing processes and enhancing sustainability. Crucial to this is development of an end-to-end data platform for storing, processing and analyzing key information, and then using it for strategic planning, modeling and forecasting.

Azure also digs into the details of data management. For example, with tire and mobility solutions stalwart Bridgestone, Azure is partnering on a large-scale digital transformation program aimed at improving operations, modernizing processes and enhancing sustainability. Crucial to this is development of an end-to-end data platform for storing, processing and analyzing key information, and then using it for strategic planning, modeling and forecasting.

The Collaborative Advanced Powerful Platform for Analytics (CAPPA) works as a “single point of truth” for Bridgestone decision-making. It’s powered by a range of Microsoft technologies, including Azure Databricks, Azure Purview and Azure Synapse Analytics. “CAPPA was born from the need to centralize all our information, harness key insights based on it and then use them to create meaningful change across our operations,” says Onkar Ambekar, Bridgestone EMIA director of Data & Analytics.

“To do that, we decided to build a data lake where we can collect and store information from various parts of our business – from the tire and rubber business to the manufacturing side, the supply chain and other areas.”

Once the data is collected – using Azure Databricks – Bridgestone can then analyze it and leverage it to both drive internal efficiencies and improve customer services.

In the end, for Microsoft Azure, it’s all about delivering enhanced, cloud-based computing capabilities for manufacturers, capabilities that extend from the foundational, data science level through to running advanced simulation and design applications on the most powerful hardware. It’s a cloud computing platform, yes, it’s also an evolving ecosystem perpetually provisioned with state of the art HPC-class

technologies.