Over at Argonne, Jared Sagoff writes that automotive manufacturers are leveraging the power of DOE supercomputers to simulate the combustion engines of the future. “As part of a partnership between the Argonne, Convergent Science, and Parallel Works, engine modelers are beginning to use machine learning algorithms and artificial intelligence to optimize their simulations. Now, this alliance recently received a Technology Commercialization Fund award from the DOE to complete this important project.”

Towards Exascale Engine Simulations with NEK5000

In this video from the HPC User Forum in Detroit, Muhsin Ameen from Argonne National Laboratory presents: Towards Exascale Engine Simulations with NEK5000. “High-order methods have the potential to overcome the current limitations of standard CFD solvers. For this reason, we have been developing and improving the spectral element code NEK5000 for more than 30 years now.”

Supercomputing More Fuel-Efficient Engines at GM

Ronald Grover from GM gave this talk at the HPC User Conference. “Ronald Grover his colleagues at GM are using the Titan supercomputer at the Oak Ridge Leadership Computing Facility (OLCF), a US Department of Energy (DOE) Office of Science User Facility at DOE’s Oak Ridge National Laboratory (ORNL), to improve combustion models for diesel passenger car engines with an ultimate goal of accelerating innovative engine designs while meeting strict emissions standards.”

Let’s Talk Exascale: Transforming Combustion Science and Technology

In this episode of Let’s Talk Exascale, Jackie Chen from Sandia National Laboratories describes the Combustion-Pele project, which uses predictive simulation for the development of cleaner-burning engines. “Almost all practical combustors operate under extremely high turbulence levels to increase the rate of combustion providing high efficiency, but there are still outstanding challenges in understanding how turbulence affects auto-ignition.”

Supercomputing Better Engines at Argonne

Researchers are using Argonne supercomputers to jump-start internal-combustion engine designs in the name of conservation. “Improving engine efficiencies by even a few percentage points can take a big chunk out of our carbon footprint. We are working on a proof-of-concept to demonstrate how simulating several thousand engine configurations simultaneously can really help engineers zero in on the optimum engine designs and operating strategies to maximize efficiency while minimizing harmful emissions.”

Supercomputing Complex Diesel Injection Mist at Army Research Lab

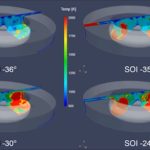

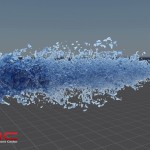

The ability to study complex interactions inside a diesel engine gives Army scientists a new perspective that may help design more fuel efficient and effective engines. Using state-of-the-art supercomputers, Army scientist Dr. Luis Bravo led efforts to create simulations highlighting the first year of his project, allowing them to investigate the jet fuel spray breakup process with microsecond time fidelity and sub-millimeter resolution, while generating petabytes of data.

ISC 2016 Keynote to Showcase Women’s Excellence in Computational Science

Today the ISC 2016 conference announced that their Tuesday keynote session will highlight contributions from female researchers and scientists in advancing the field of computational science. “This year, Dr. Jacqueline H. Chen, a distinguished member of technical staff at Sandia National Laboratories, has been invited to keynote on Tuesday, June 21, on the topic of advancing the science of turbulent combustion using petascale and exascale simulations.”

Allinea Forge Sparks Convergent Science Combustion Simulation

Convergent Science reports that the company has adopted the Allinea Forge development tool suite. As the leader in internal combustion engine (ICE) simulation, Convergent Science is using Allinea to increase the capability and performance of the company’s CONVERGE software.

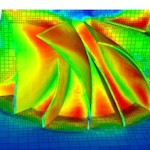

Pushing the Boundaries of Combustion Simulation with Mira

“Researchers at the U.S. Department of Energy’s Argonne National Laboratory will be testing the limits of computing horsepower this year with a new simulation project from the Virtual Engine Research Institute and Fuels Initiative (VERIFI) that will harness 60 million computer core hours to dispel those uncertainties and pave the way to more effective engine simulations.”

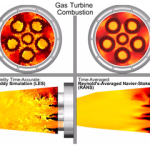

GE and Cascade Optimize Gas Turbine Simulation

Today GE announced a multi-year joint development agreement with Cascade Technologies to improve combustion simulation software. With new visualaztion capabilities, engineers can virtually look inside a gas turbine as it operates and gain a better understanding of the turbulent fluid, chemical and acoustic processes occurring within advanced, low-emissions gas-turbine combustion systems.