Advanced simulation software is helping Tokamak Energy to develop a pioneering clean energy power plant based on nuclear fusion. Using the electromagnetic design and analysis facilities provided by the Cobham Technical Services Opera software, critical design issues are being resolved at an early stage to help prototype an ultra-compact spherical tokamak in a tiny footprint that is about the size of a house room.

Advanced simulation software is helping Tokamak Energy to develop a pioneering clean energy power plant based on nuclear fusion. Using the electromagnetic design and analysis facilities provided by the Cobham Technical Services Opera software, critical design issues are being resolved at an early stage to help prototype an ultra-compact spherical tokamak in a tiny footprint that is about the size of a house room.

The Cobham Technical Services Opera software is helping Tokamak Energy to reduce the very high costs associated with prototyping a new fusion power plant concept,” said Paul Noonan, R&D Projects Director for ST40. “After we have built our new prototype, we hope to have assembled some profoundly exciting experimental and theoretical evidence of the viability of producing fusion power from compact, high field, spherical tokamaks.”

Tokamak Energy grew out of the Culham Laboratory, home of JET, the world’s most powerful operating tokamak. With the advent of high temperature superconductors (HTS), the company’s founders realized that it is theoretically possible to produce a tokamak that performs similarly to existing research machines – but with a much smaller spherically-shaped reaction chamber.

The controlled fusion process inside a tokamak takes place in a plasma that is held in place by a very powerful electromagnetic field. The Cobham Technical Services Opera simulation software is helping Tokamak Energy to design this magnetic confinement system.

A key step on the path to the commercial spherical tokamak is the current construction of a working prototype – the ST40 – that will be used to prove that the extreme high temperature required for fusion reactions can be achieved inside a compact tokamak.

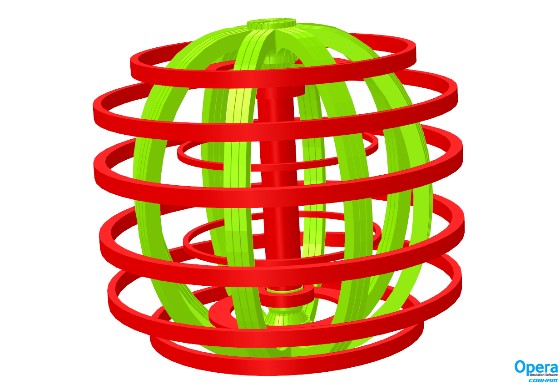

As part of this design step, Tokamak Energy used the Cobham Opera simulation software to assess the electromagnetically induced forces and field profile of the ST40 tokamak’s magnetic confinement system. To reduce costs the prototype does not use HTS coils, but employs a single massive copper conductor for each toroidal field coil. The final HTS coils will need to be mechanically supported with minimum heat transfer. This prototype will help Tokamak Energy to investigate a self-supporting structure that is able to cope with the large internal mechanical forces generated but which minimizes thermally conductive connections to the room-temperature world. A consequence of the massive copper conductors is that current density and the resulting Lorentz force density is non-uniform – necessitating a high precision simulation.

The magnetic confinement system for ST40 is around 2.6 meters high and 2.8 meters in diameter and will have 24 toroidal field coils, arranged in eight groups of three, as well as multi-turn poloidal field and central solenoid coils. Before finalizing the coil designs, Tokamak Energy modeled and simulated several variations, each examining the fields and forces at different times in the operating scenario. Three dimensional simulation was employed for accuracy, using a 45 degree ‘wedge’ of the symmetrical spherical geometry for computational speed. Even so, the finite element design models used are extremely large in order to achieve exceptional precision – and involve around 10 million elements. These huge 3D models were simulated in around 15 hours using the Cobham Technical Services Opera software running on standard PC technology.

The ST40 is now being assembled and is due to start operating early in 2017. The initial target is to create a plasma that is hotter than the center of the sun, and then push on to reach 100 million degrees.

To speed design and prototyping, Cobham helped Tokamak Energy to build and simulate models of the ST40. Chris Riley from the Cobham Technical Services team, who worked on the engineering project adds, “Developing highly-complex and unique equipment like a tokamak would be prohibitively expensive and time consuming without the aid of advanced computer-aided engineering tools. The performance of the magnetic confinement system is critical to the operation of the spherical tokamak; we are proud to that our Opera simulation software has been chosen to support Tokamak Energy’s engineering decisions.”

Sign up for our insideHPC Newsletter