A European research consortium has announced progress in the development of sustainable fuels.

The Center for Excellence in Combustion (CoEC), coordinated by the Barcelona Supercomputing Center (BSC) and comprised of 11 supercomputing centers, laboratories and universities, applies supercomputing technologies to developing advanced simulation software that support the decarbonization goals of the European Union in the energy and transportation sectors.

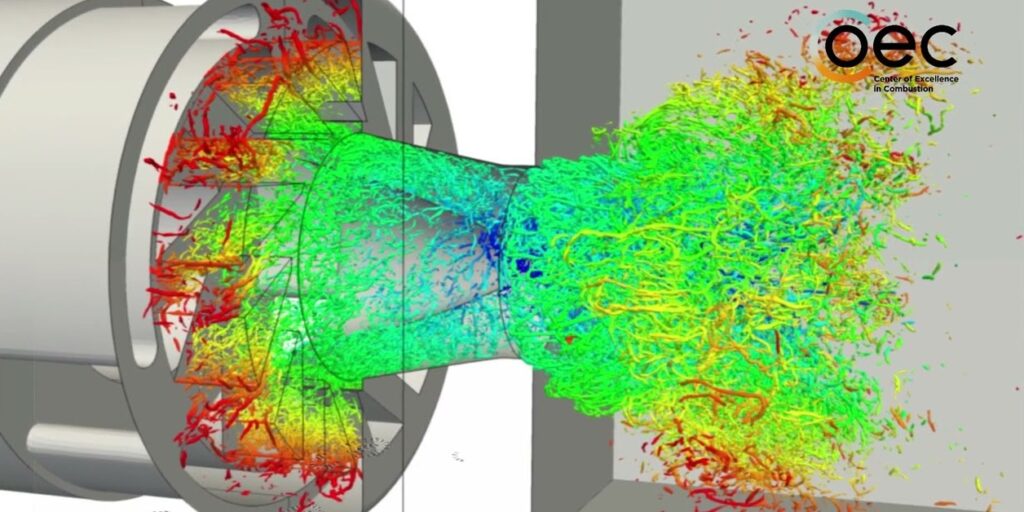

The organization reported what it said is a “notable breakthrough” linked to carbon-free hydrogen combustion. “…high-fidelity simulations were conducted to explore hydrogen combustion using a lab-scale gas turbine combustor model that had been experimentally characterized” at Technische Universität Berlin.

“The numerical results from these simulations contributed to understanding the primary characteristics of the flame and major chemical pathways for NOx formation, shedding light onto its stabilisation mechanisms, and revealing insights into flame resistance,” CoEC said.

The organization also said progress is being made in the understanding of carbon nanoparticles – i.e., soot – are formed in aero-engines. A collaboration of several universities and research centers in Europe, along with BSC, used simulations to generate “numerical results (to) guide the development of mitigation strategies, offering valuable insights for optimising the burner’s operation and limiting the emission of soot particles.”

The CoEC also said project has focused on development of software and methodologies to assist industrial partners in designing the next generation of hydrogen turbines for power generation and aviation propulsion. These tools can also support the operation and optimization of wind farms and enhance the efficiency of chemical reactors.

The CoEC also said project has focused on development of software and methodologies to assist industrial partners in designing the next generation of hydrogen turbines for power generation and aviation propulsion. These tools can also support the operation and optimization of wind farms and enhance the efficiency of chemical reactors.

Additionally, CoEC has worked on HPC codes to explore the combustion of iron powder and hydrogen. This cyclic, carbon-free fuel holds the potential for storing and transporting renewable energy, and “understanding of its combustion is crucial for developing burner technology. Simulations of combustion of iron particles in CoEC’s codes has provided insights into iron powder flames, opening avenues for simulating iron powder combustion in industrial applications.”

CoEC said results also have been generated by a project connected to visualization of the extreme amount of data from exascale-class simulations of nekCRF, a reactive flow solver. Part of this work involved developing new new simulation code so that it makes efficient use of GPU chips.

“All exascale supercomputers use GPUs for most of their performance, in contrast to petascale systems that use CPUs for most of their performance,” the CoEC said. “Simply optimising code developed for CPU systems to run efficiently on GPUs is typically impossible. Therefore, new simulation codes must be developed, which is highly non-trivial for complex simulations such as combustion applications.”

Several partners contributed nekCRF making efficient use of GPUs, accelerating time to a solution, CoEC said. “A particular focus has been placed on optimising nekCRF for the hardware of Europe’s first exascale supercomputer, JUPITER, to enable one of the largest combustion simulations in the world and the largest ever in Europe.

“Simulation has become the third scientific pillar alongside theory and experiment,” said Christian Hasse, professor in the Department of Mechanical Engineering, Darmstadt University of Technology, Germany, and one of the team leaders of CoEC. “We are just at the beginning of developing hydrogen aero gas turbines. The combination of unique experiments and, particularly important for CoEC, high-performance computing, provides insights into combustion processes that were unthinkable 10 years ago.”