AI technologies are being used to help develop Next-gen nuclear energy systems that could help reduce our dependency on fossil fuels. In this special guest feature, Dawn Levy and Weiju Ren from ORNL explore the challenges and opportunities in sharing nuclear materials knowledge internationally.

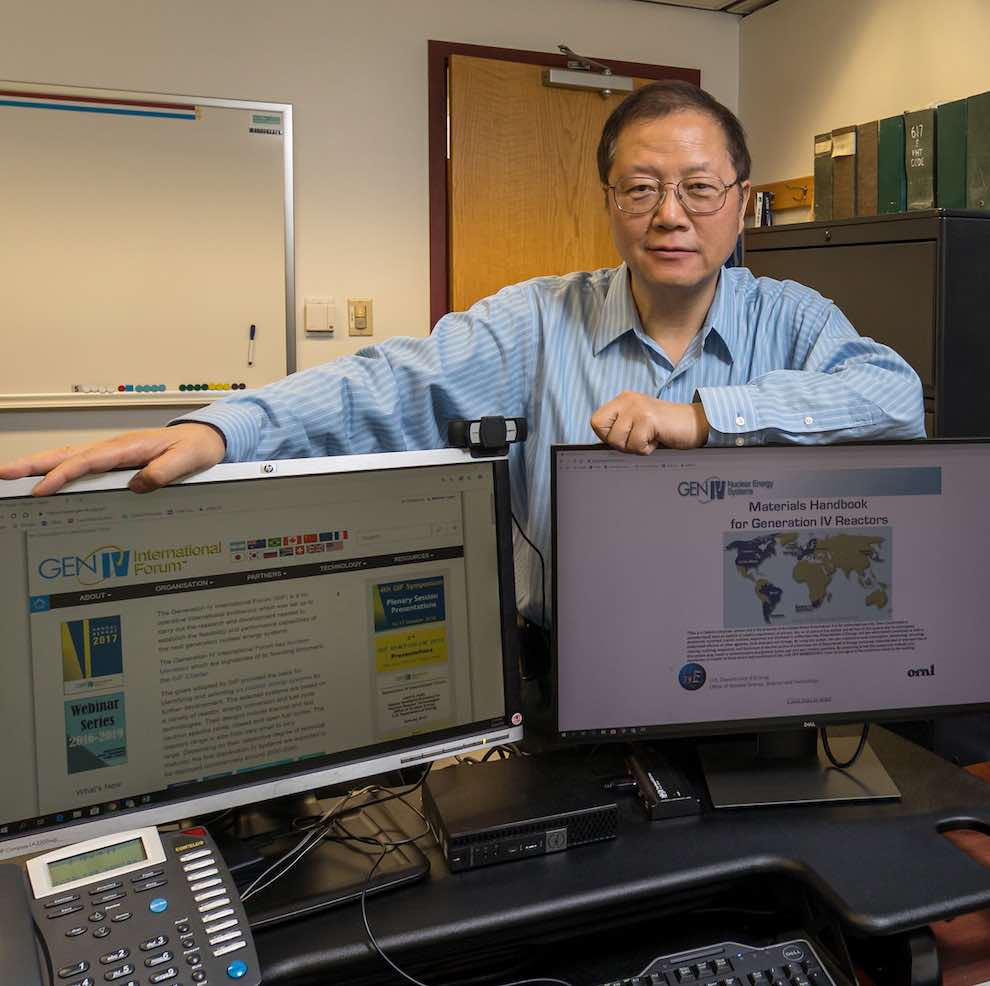

Weiju Ren’s knowledgebase is making the nuclear world safer. Called DOE’s Gen IV Materials Handbook, it manages data about structural materials for the Very High Temperature Reactor. Credit: Carlos Jones/Oak Ridge National Laboratory, U.S. Dept. of Energy

Six new nuclear reactor technologies are set to deploy for commercial use between 2030 and 2040. Called Generation IV nuclear reactors, they will operate with improved performance at dramatically higher temperatures than today’s reactors. Weiju Ren of the Department of Energy’s Oak Ridge National Laboratory manages an operation by which global participants share research and development (R&D) for structural materials to be used in a Gen-IV reactor called the Very High Temperature Reactor (VHTR)—with graphite moderators and a once-through uranium fuel cycle. He heads DOE’s Gen IV Materials Handbook, a project managing more than $180 million worth of structural materials information for the VHTR.

“Handbook” is a misnomer harkening back to the DOE project’s early days, when nuclear materials data were archived in three-ring binders. Today, the aim is to manage digitized data in machine-readable formats in a “knowledgebase”—an organized collection of information that maintains interrelationships and logic among the constituents in a manner consistent with human cognitive processes to ensure effective processing, confident interpretation and correct use.

The United States hosts the project’s data on a website funded by the DOE Office of Nuclear Energy. The project is a U.S. contribution to the Generation IV International Forum (GIF), a cooperative enterprise with 14 signatories seeking development of six Gen-IV reactor concepts including the VHTR. Its active member are Australia, Canada, China, the European Atomic Energy Community, France, Japan, Russia, South Africa, South Korea, Switzerland and the United States. Its non-active members are Argentina, Brazil and the United Kingdom. GIF members carry out R&D to establish feasibility and performance of next-gen nuclear energy systems.

Dawn Levy: What’s the general state of nuclear power as an industry—dying, surviving, thriving?

Weiju Ren: In some countries, it’s fine. In others, the public doesn’t think it’s a good idea. Countries like France and China are eager for nuclear power. In the United States, it struggles because it must compete with low-cost natural gas and several other sources of energy. Still, the United States needs to develop this technology because there is an international market that we don’t want to lose. We also want to keep our technical edge in this area.

Dawn Levy: What are Gen IV materials?

Weiju Ren: Most Gen IV reactors are designed for a very long service life—40 to 60 years—operating at up to 950 C [1742 F] to achieve greater energy efficiency than today’s reactors. Ambitious developers of some VHTRs envision service at even higher temperatures. In comparison, most current reactors operate at or below about 350 C [662 F]. Gen IV materials are structural materials for high-temperature services in these reactors, but they’re not limited to nuclear applications. They are also used in fossil energy plants and aerospace components.

Dawn Levy: How did your project evolve from a ‘handbook’ to a ‘knowledgebase’?

Weiju Ren: After DOE’s Gen IV reactors program started in 2002, we had a workshop with stakeholders to discuss how we should manage materials data for U.S. reactor development. For the previous generation of reactors, during the 1970s and 1980s, DOE successfully developed the Nuclear Systems Materials Handbook under the leadership of Oak Ridge National Laboratory. It’s a huge set of volumes in three-ring binders that occupy one and a half shelves of my bookcase. The consensus at the workshop was that we need to repeat that success for Gen IV reactor development. They gave me the task. I told them, ‘This is a different era. We cannot repeat the three-ring binders. We need to do it electronically and develop a web-based database.’ Everybody agreed, but the “handbook” name stuck. It’s really a database that gradually evolved into a knowledgebase.

Dawn Levy: What’s a difference between a database and a knowledgebase?

Weiju Ren: A knowledgebase is more than a database. Data are just symbols representing observations or the products of observations. Knowledge is not only data, but also people’s understanding of the data. In other words, it is data endowed with meaning and purpose for the recipient—information in a structured form consistent with human cognitive processes, as opposed to simple lists of symbols. Managing interrelationships among the information elements and information pedigree in a knowledgebase can ensure that data are unequivocally interpreted and correctly used, which is extremely important for nuclear safety.

Dawn Levy: Why was ORNL the right place to create a materials knowledgebase?

Weiju Ren: We have a history of materials development dating back to World War II, an extremely rich data archive, and a lot of people who are very skilled and knowledgeable in materials. Subsequent developments in fossil and nuclear energy kept that materials-intensive capability at ORNL. I don’t see any other national laboratory having that volume of expertise in materials. We have world-class materials R&D facilities and generate impressive amounts of materials information every year.

After the workshop with stakeholders, I created a demo knowledgebase for DOE’s Office of Nuclear Energy to evaluate. They liked it and decided to support us. Then I presented it to GIF’s VHTR Materials Project Management Board. The Board carefully considered my demo and other members’ systems, reaching a unanimous conclusion to adopt the Gen IV Materials Handbook as the international repository for VHTR structural materials R&D data.

Dawn Levy: What information do researchers share through the knowledgebase? If the community has concerns about sharing, how do you address them?

Weiju Ren: The information we put into the Gen IV Materials Handbook is largely the R&D reports from each signatory’s Gen IV nuclear program and the materials data associated with those reports. We address information security concerns from technical and managerial aspects. Technically, we apply strict access control to every level of information. If a data contributor says, ‘We don’t want Group X to see these two records or this datapoint,’ the access controller can hide the two records or the datapoint from Group X. Managerially, our operation protocol requires three-party collaboration to authorize a new user. We have an approver, a registrar and an executor. The approver is normally the representative of the signatory. They send the approval of a new user to me. I register that approval, and then send a request to ORNL IT support to execute the access setting for that user. If one us didn’t do our job, the new user can’t initiate login.

Dawn Levy: You also lead development of a materials properties database of the American Society of Mechanical Engineers (ASME), a not-for-profit organization with members from diverse industries who share knowledge and develop solutions for the global engineering community. How did that come about?

Weiju Ren: ASME ran into a serious problem in materials data management for its codes and standards. They heard I had developed this knowledgebase and asked for help. Many U.S. industries rely heavily on ASME codes and standards. A major one is the Boiler and Pressure Vessel Code, which regulates design and construction in industries including fossil energy, nuclear energy and petrochemical processing. So I jumped in and with a vice president of ASME Standards Technology created a plan for developing the ASME Materials Properties Database in our knowledgebase system. The development started on the ORNL network several years ago [through what was then called DOE Work for Others, now called DOE Strategic Partnership Projects]. So far, ASME is happy. I’m glad that tax dollar investment can be leveraged by U.S. industries this way because ASME views this as a huge help from DOE. Reciprocally, ASME allows ORNL to use its database to support DOE projects.

Dawn Levy: What would you like to see happen in the next two to five years with this effort?

Weiju Ren: We expect the international collaboration for VHTR to extend to 2023. The Gen IV Materials Handbook will reach maturity, and the international contributions will be preserved. If we can also leverage the system to preserve our abundant historical materials data and data from new programs, that will benefit generations to come by avoiding redundant data development, which can save a lot of R&D funds. Unfortunately, much of ORNL’s historical data is in hardcopy; the paper is decaying and periodically is scrapped to save storage space. Also, some people with firsthand knowledge to correctly interpret those archives have retired or passed away. I want to save that knowledge electronically, but I don’t have adequate manpower to scan and prepare the archives for uploading, let alone task people who understand the data with inputting it in a machine-readable and unequivocally interpretable fashion.

Dawn Levy: Could the knowledgebase help the Nuclear Regulatory Commission (NRC) accelerate approval of new reactor designs?

Weiju Ren: Yes. Information contributed to the Gen IV Materials Handbook will be used for development of reactors in compliance with the ASME nuclear code. Before NRC reviews a reactor licensing application, it must endorse the ASME code used to design and construct the reactor. So this knowledgebase has become very important for both NRC and ASME. Recently, DOE approved NRC access to the U.S. data in the Handbook to prepare for licensing advanced non-light water reactors.

Dawn Levy: What problems arise when international signatories input data?

Weiju Ren: Different countries may have different procedures for testing materials and use different terminologies. That creates a danger of misinterpretation and misuse of data with different backgrounds. Furthermore, posterity can no longer consult data contributors to question ambiguities. As we develop the knowledgebase, we focus on solutions to these problems. I ask each country to appoint a data manager to communicate with me and make sure we fully understand their data for uploading. We develop an online help menu for terminology that may have multiple interpretations. We also create a sophisticated hyperlink network to maintain complicated interrelationships among informational elements so users can easily find related information to fully understand the data for its correct use.

Dawn Levy: Is there a place for artificial intelligence (AI) in this work?

Weiju Ren: AI is promising for creation and analysis of new materials or optimal control of materials processing in, for example, integrated computational materials engineering and additive manufacturing. AI heavily relies on the processes of computational learning, reasoning and self-correction, which require considerable manipulation of data in an automated or semiautomated fashion—a great challenge.

The knowledgebase that we have can provide a good foundation for rising to this challenge. We manage materials data in a machine-readable fashion with information elements at their lowest meaningful levels for individual and collective manipulation by computer algorithms. Computational simulation giant ANSYS recently purchased the company that produces the database toolkit we are using. Obviously, ANSYS sees the importance of materials data technology in computational simulations.

I can envision efficient and even creative interactions between the knowledgebase system and the simulation system in the future. Currently most data sets are loaded into a simulation system through typing, copying, pasting, uploading, and so on. But if the knowledgebase system manages data in a machine-readable fashion, various smart interfaces can be developed to automate massive data exchange between a simulation system and the knowledgebase system. That can considerably enhance computational learning, reasoning and self-correction for AI.

Source: ORNL

Sign up for our insideHPC Newsletter