Over at The UberCloud, Wolfgang Gentzsch writes that researchers are using HPC in the Cloud in a revolutionary new way for the design of bioreactors.

It’s amazing to think of all the products created in bioreactors. The medications we take, the beer we drink and the yogurt we eat are all made in bioreactors optimized for the manufacturing of these products. Unfortunately, optimizations take a lot of work and data. In a new HPC Cloud project, engineers from ANSYS with support from UberCloud performed an extensive Design of Experiments in Microsoft’s Azure Cloud.

It’s amazing to think of all the products created in bioreactors. The medications we take, the beer we drink and the yogurt we eat are all made in bioreactors optimized for the manufacturing of these products. Unfortunately, optimizations take a lot of work and data. In a new HPC Cloud project, engineers from ANSYS with support from UberCloud performed an extensive Design of Experiments in Microsoft’s Azure Cloud.

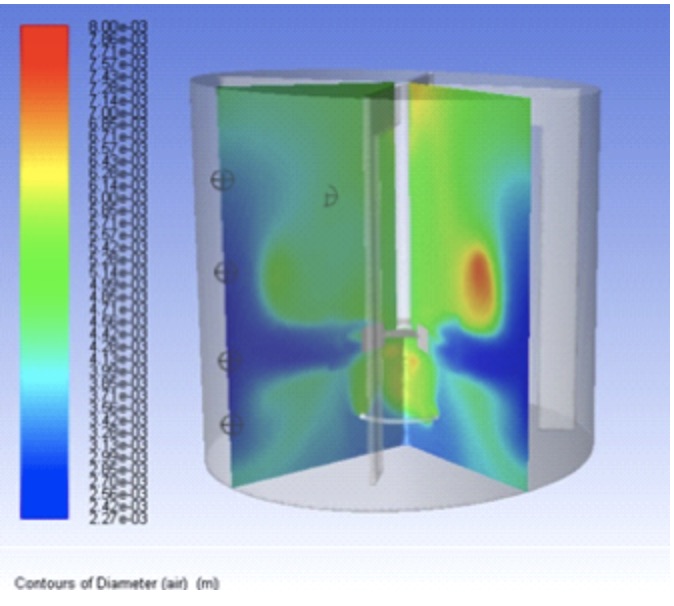

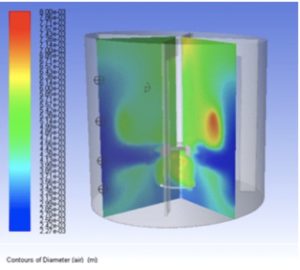

Bioreactors are the heart of every pharmaceutical manufacturing process. One goal of a bioreactor is to operate at process conditions that provide sufficient oxygen to the suspended cells. The design space of a bioreactor defines the relationship between the input and output parameters of the cell culture process. This knowledge is used to establish and maintain consistent process (and therefore product) quality.

The design space typically relies on a design of experiments (DOE) approach to characterize the interdependencies between tank design and process operating conditions. This can be an expensive and time-consuming exercise to perform in the lab, especially at manufacturing scale.

The pharmaceutical industry has adopted computational fluid dynamics (CFD) modeling as a cost-saving option that can also reduce the risk associated with scale-up and day-to-day operations. However, the simulation time and compute resources required to explore the relationships between various process parameters can be quite extensive. Therefore, UberCloud case study 206 reviews the use of HPC to establish the design space of a production scale sparged bioreactor.

The pharmaceutical industry has adopted computational fluid dynamics (CFD) modeling as a cost-saving option that can also reduce the risk associated with scale-up and day-to-day operations. However, the simulation time and compute resources required to explore the relationships between various process parameters can be quite extensive. Therefore, UberCloud case study 206 reviews the use of HPC to establish the design space of a production scale sparged bioreactor.

End-user in this project was Sravan Kumar Nallamothu, senior application engineer at ANSYS and a specialist in modeling mixing in stirred tanks and gas-liquid multiphase flows. He used Azure’s data center resources in Singapore because this is relatively close to Sravan’s ANSYS office in Pune, India.

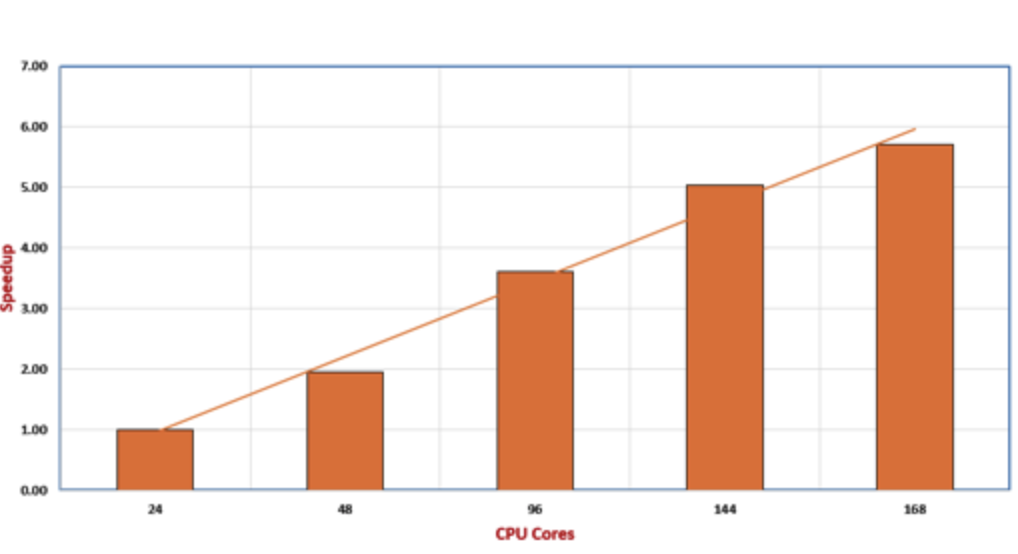

Simulations were executed by running the ANSYS Fluent UberCloud container, starting on one node (16 cores) and the last run was on 16 nodes (256 cores). Azure instance nodes were Standard_H16r, interconnected by FDR InfiniBand (56 Gbps bandwidth).

Each simulation — running on 168 cores in the cloud — took less than an hour. As a result, mapping out the whole design space took less than 12 hours (versus more than a week on the user’s workstation). To learn more about how UberCloud can speed up ANSYS simulations, read the ANSYS Blog.