Today the High Performance Computing for Energy Innovation program (HPC4EI) announced the nine public/private projects awarded more than $2 million from the DOE, with aims of improving energy production, enhancing or developing new material properties and reducing energy usage in manufacturing.

Today the High Performance Computing for Energy Innovation program (HPC4EI) announced the nine public/private projects awarded more than $2 million from the DOE, with aims of improving energy production, enhancing or developing new material properties and reducing energy usage in manufacturing.

The projects represent the first joint round of funding for the HPC4EI Program, the umbrella entity for the HPC4Manufacturing (HPC4Mfg) and HPC4Materials (HPC4Mtls) programs, headed out of Lawrence Livermore National Laboratory (LLNL). The program is funded through the Advanced Manufacturing Office within DOE’s Office of Energy Efficiency and Renewable Energy (EERE), and DOE’s Vehicle Technologies Office and Office of Fossil Energy, and includes eight other DOE partner laboratories. The program aims to leverage the national laboratories’ world-class computational resources to advance the national energy agenda and increase American competitiveness.

We see increasing interest by both industry and the DOE Applied Energy Offices to leverage the world-class computational capabilities of leading national laboratories to address the significant challenges in improving the efficiency of our national energy footprint,” said HPC4EI Director Robin Miles.

The five HPC4Mfg projects funded by the DOE/EERE’s Advanced Manufacturing Office are:

- In a follow-on project, LLNL will continue working with Applied Materials Inc. on Phase II of developing predictive modeling capabilities for the advanced film deposition technique High Power Impulse Magnetron Sputtering, which can be used to deposit materials for energy-efficient lighting such as high efficiency LEDs and in energy-efficient non-volatile memory storage devices.

- Lawrence Berkeley National Laboratory and Ferric, Inc. will partner to develop analytical tools that will combine traditional electromagnetic finite-element analysis with micromagnetic simulation to improve high conversion of efficiency of integrated voltage regulators, and the energy efficiency of the data center processors they supply.

- Oak Ridge National Laboratory (ORNL), Gopher and the Gas Technology Institute will partner to develop a high-fidelity computational fluid dynamics model of a directly fired reverberatory-style secondary lead furnace, with an aim of increasing the productivity of such furnaces.

- Argonne National Laboratory and Eastman will collaborate on developing open-source software-based models of a gas atomizer based on ongoing work being performed at Eastman. The models and simulations will be used to gain insight into the physics of the phenomena and to optimize the process, with a goal of achieving a minimum 2 percent improvement in energy production.

- Ames National Laboratory and Praxair Surface Technologies Inc. will work to significantly enhance the efficiency, precision and quality of metal powder production through computational fluid dynamics simulations. The goals are to improve powder size range yield and the quality of metal powder, reducing material and energy production costs.

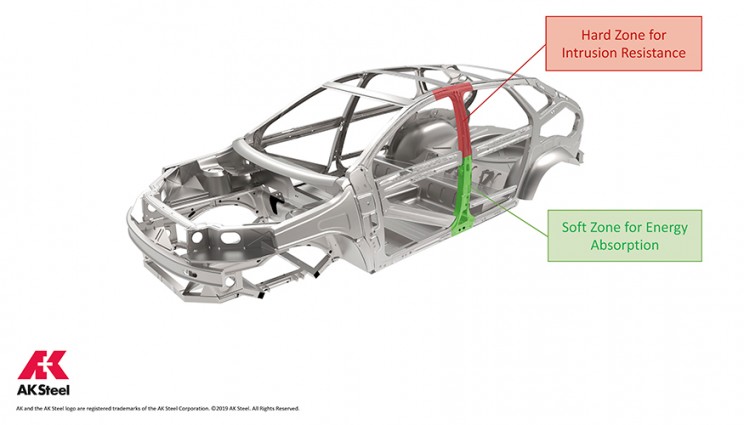

In a newly funded HPC4Materials project, Oak Ridge National Laboratory and AK Steel will partner to develop microstructure-based transformation models to predict austenite stability. The project will be funded by the Department of Energy’s Vehicle Technologies Office. Lawrence LIvermore National Laboratory heads the HPC4EI Program, the umbrella entity for the HPC4Manufacturing (HPC4Mfg) and HPC4Materials (HPC4Mtls) programs. Illustration courtesy of AK Steel

The four HPC4Mtls projects, funded by DOE’s Vehicle Technologies Office and Office of Fossil Energy, are:

- LLNL and Pacific Northwest National Laboratory will work with PPG Industries Inc. to apply classical molecular dynamics simulations and density functional tight-binding calculations to fundamentally understand the influence of water on the properties of epoxy-based adhesives joined to lightweight substrates. The goals are to mitigate corrosion and thermal expansion issues associated with joining dissimilar lightweight materials and to improve understanding of the chemistry that occurs in the adhesive as the joint ages. The project will receive funding from DOE’s Vehicle Technologies Office.

- ORNL and AK Steel will partner to utilize the phenomenon of altering the transformation characteristics of advanced high-strength steels by varying process parameters to develop microstructure-based transformation models capable of predicting austenite stability as a function of chemical composition, strain level, deformation mode, temperature and strain rate. The project also will be funded by the Vehicle Technologies Office.

- ORNL and Electric Power Research Institute Inc. will collaborate to develop detailed modeling of the thermal hydraulics, heat transfer and steam-side oxide growth in Heat Recovery Steam Generators to gain a better understanding of temperature distribution, ensure effective materials selection, develop new materials or repurpose of existing materials and determine specific regions requiring replacement and/or new alloy concepts. Funding will come from the DOE’s Office of Fossil Energy.

- The National Renewable Energy Laboratory will partner with NovoNutrients to improve computational fluid dynamics models for identifying optimal efficient and productive bioreactor designs and operating conditions for NovoNutrients’ gas fermentation technology to enable commercial conversion of CO2 into aquaculture and animal feed. The project also will be funded by the Office of Fossil Energy.

DOE/EERE’s Advanced Manufacturing Office is contributing $1.35 million for the HPC4Mfg projects. The Vehicle Technologies Office and the Office of Fossil Energy will fund $600,000 apiece for the HPC4Mtls projects. Industry partners were required to make in-kind contributions of at least 20 percent of project costs.

To date, DOE has provided $25 million for 79 public/private projects to 65 different partners through the HPC4Mfg and HPC4Mtls programs.